Cross Linked Poly: A Comprehensive Overview

Cross linked poly, often abbreviated as CPL, is a type of polymer that has gained significant attention in various industries due to its unique properties and applications. In this article, we will delve into the details of cross linked poly, exploring its structure, properties, manufacturing process, and applications across different sectors.

Structure of Cross Linked Poly

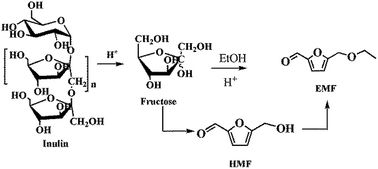

Cross linked poly is a thermosetting polymer, which means it undergoes a chemical change during the curing process, resulting in a rigid and durable material. The structure of cross linked poly is characterized by the presence of cross links between polymer chains. These cross links create a three-dimensional network, which contributes to the material’s strength and stability.

One of the key components of cross linked poly is the monomer, which is a small molecule that can be polymerized to form a long chain. Common monomers used in the production of cross linked poly include bisphenol A (BPA) and epoxy resins. These monomers undergo a chemical reaction to form a network of cross links, resulting in the final cross linked poly product.

Properties of Cross Linked Poly

Cross linked poly exhibits a wide range of properties that make it suitable for various applications. Some of the key properties of cross linked poly include:

| Property | Description |

|---|---|

| High Strength | Cross linked poly is known for its high tensile strength, making it suitable for applications that require resistance to mechanical stress. |

| Chemical Resistance | This material is highly resistant to chemicals, making it ideal for use in environments where exposure to corrosive substances is common. |

| Heat Resistance | Cross linked poly can withstand high temperatures without deforming or losing its structural integrity. |

| Insulation Properties | Cross linked poly is an excellent electrical insulator, making it suitable for use in electrical and electronic applications. |

These properties make cross linked poly a versatile material that can be used in a wide range of applications, from automotive parts to construction materials.

Manufacturing Process of Cross Linked Poly

The manufacturing process of cross linked poly involves several steps, including monomer preparation, polymerization, and curing. Here is a brief overview of the process:

-

Monomer Preparation: The monomers used in the production of cross linked poly are first prepared by mixing them with other chemicals to create a suitable mixture for polymerization.

-

Polymerization: The prepared monomer mixture is then subjected to a polymerization process, where the monomers react to form long polymer chains. This process can be carried out using various methods, such as solution polymerization, suspension polymerization, or emulsion polymerization.

-

Curing: After the polymerization process, the polymer chains are cross linked to form a three-dimensional network. This is achieved by heating the polymer to a specific temperature and pressure, which allows the cross links to form and the material to cure.

The curing process is crucial in determining the final properties of the cross linked poly material. The temperature and pressure used during curing can be adjusted to achieve the desired balance between strength, flexibility, and other properties.

Applications of Cross Linked Poly

Cross linked poly has a wide range of applications across various industries. Some of the key applications include:

-

Automotive Industry: Cross linked poly is used in the manufacturing of automotive parts, such as bumpers, dashboards, and door panels, due to its high strength and impact resistance.

-

Construction Industry: This material is used in construction applications, such as waterproofing membranes, roof coatings, and flooring materials, due to its chemical and heat resistance.

-

Electrical and Electronic Industry: Cross linked poly is an excellent electrical insulator and is used in the production of electrical cables, transformers, and other electrical components.

-

Medical Industry: Cross linked poly is used in medical applications, such as surgical gloves, catheters, and implants, due to its biocompatibility and resistance to chemicals.