Chain Link Fence Gates: A Comprehensive Guide

Chain link fence gates are an essential component of any chain link fence system. They serve as the entry and exit points, providing security and convenience. Whether you’re looking to install a new gate or replace an old one, understanding the different types, materials, and installation processes is crucial. In this article, we’ll delve into the various aspects of chain link fence gates to help you make an informed decision.

Types of Chain Link Fence Gates

Chain link fence gates come in various types, each designed to cater to different needs and preferences. Here are some of the most common types:

- Sliding Gates: These gates move horizontally along a track, making them ideal for areas with limited space. They are available in single and double leaf designs.

- Swing Gates: Swing gates open and close like a door, either to the left or right. They are suitable for wider spaces and can be single or double leaf.

- Roller Gates: Roller gates consist of a series of horizontal chains that roll up into a coil. They are perfect for areas with limited headroom and can be automated.

- Security Gates: Security gates are designed with heavy-duty materials and reinforced frames to provide enhanced security. They are ideal for high-risk areas.

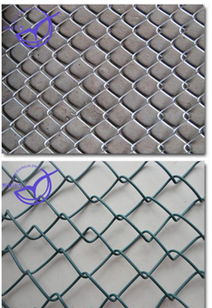

Materials Used in Chain Link Fence Gates

The choice of material for your chain link fence gate can significantly impact its durability, appearance, and maintenance requirements. Here are some common materials used:

- Galvanized Steel: This is the most popular material for chain link fence gates due to its strength, durability, and resistance to corrosion. It comes in various finishes, including black, green, and brown.

- Aluminum: Aluminum gates are lightweight, corrosion-resistant, and require minimal maintenance. They are an excellent choice for areas with coastal exposure or in warm climates.

- Wood: Wooden gates offer a classic, rustic look and can be stained or painted to match your home’s exterior. However, they require regular maintenance to prevent rot and decay.

- Wrought Iron: Wrought iron gates are highly durable and offer a timeless, elegant appearance. They are, however, more expensive and require regular maintenance to prevent rust.

Installation Process

Installing a chain link fence gate involves several steps, including measuring, preparing the posts, and assembling the gate. Here’s a brief overview of the process:

- Measuring: Measure the opening width and height to determine the size of the gate you need. Add a few inches to each dimension to account for the posts and hinges.

- Preparing the Posts: Dig post holes according to the manufacturer’s instructions. Ensure the holes are deep and wide enough to accommodate the posts securely.

- Setting the Posts: Place the posts in the holes and backfill with concrete. Allow the concrete to cure for at least 24 hours before installing the gate.

- Assembling the Gate: Follow the manufacturer’s instructions to assemble the gate. Attach the hinges to the posts and the gate, and secure them with screws.

- Adjusting the Gate: Once the gate is installed, adjust the hinges and latches to ensure smooth operation and proper alignment.

Maintenance and Upkeep

Proper maintenance is essential to ensure your chain link fence gate remains in good condition. Here are some tips for maintaining your gate:

- Clean the Gate: Regularly clean the gate with a mild detergent and water to remove dirt and debris. For tougher stains, use a pressure washer.

- Inspect the Gate: Periodically inspect the gate for signs of wear and tear, such as rust, loose screws, or damaged hinges. Address any issues promptly to prevent further damage.

- Paint or Stain the Gate: If your gate is made of wood or galvanized steel, apply a coat of paint or stain every few years to protect it from the elements.

- Check the Latches and Hinges: Ensure the latches and hinges are functioning properly. Lubricate hinges as needed to keep them moving smoothly.